The Downhole Deployment Valve has been designed to eliminate the need for snubbing operations, or the need to kill the well in order to trip the drill string during underbalanced drilling operation.

During underbalanced operations, the well is allowed to flow during the drilling operations, to avoid potential formation damage. This result in a flowing or shut-in.

Pressure in the annulus at surface. With any significat pressures while tripping the string, it has been necessary to use a snubbing unit or to kill the well to avoid pipe ligth conditions.

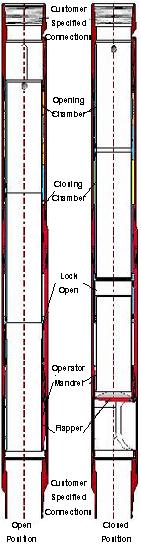

The deployment valve is run as an integral part of the casing program, allowing full bore passage for the drill bit when in the open position. When it becomes necessary to trip the drill bit when in the open position. When it becomes necessary to trip the drill string, the string is tripped out until the bit is above the deployment valve, at which time the valve is closed and the casing string above the deployment valve bled off. At this time, the drill string can be tripped out of the well without the use of a snubbing unit and at conventional tripping speeds, thus reducing rig time requirements and providing improved personnel safety.

The drill string can then be tripped back into the well until the bit is just above the deployment valve, at which time the deployment valve can be opened following pressure equalization and the drill string run in to continue drilling operations.

Additionally the deployment valve is ideal for deployment of long or complex bottom hole assemblies where mud motors, stabilizers or complex profiles make it difficult to seal on the outside of the string. Once the well is drilled the deployment valve can further be utilized for deployment of the completion system, making it possible to run long slotted liner systems, ECPs and production strings without setting a casing bridge plug. The deployment valve can either be run and cemented in place with the casing , or with a liner hanger and tie-back assembly. Once installed the valve is operated by pressure that is applied to an armored control line that runs from the valve to surface.

Válvulas de Retención para Casing.

Trip in conventionally until drill string is above Deployment Valve Close pipe rams and pressuriza well until pumping through Deployment Valve.

Open Deployment Valve flow well at surface to reduce surface pressure to safe flowing pressure. Open pipe rams an trip into well.

Begin drilling procedure.

Trip drill string out of hole until bit is above Deployment Valve.

Close Deployment Valve and bleed down casing pressure above valve. Trip drill string out of well conventionally.

- BRENT 73,06

- BRENT 73,06